The dream of establishing a permanent human presence on the Moon is inching closer to reality, but one of the most persistent obstacles remains lunar dust—a fine, abrasive, and electrostatically charged material that clings to everything it touches. Engineers and designers working on lunar colonization workwear are now prioritizing advanced sealing technologies to protect astronauts and equipment from this pervasive threat. Unlike Earth’s relatively benign dust, lunar regolith poses unique dangers due to its jagged structure and lack of erosion, making traditional sealing methods insufficient.

The Menace of Lunar Dust

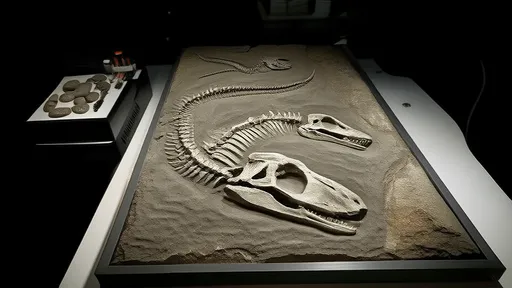

Lunar dust, or regolith, is the product of billions of years of meteorite impacts and solar radiation bombardment. Unlike terrestrial dust, which is smoothed by wind and water, Moon dust particles remain sharp and jagged. These microscopic shards can easily penetrate seals, abrade surfaces, and even interfere with machinery. During the Apollo missions, astronauts reported that the dust clung stubbornly to their suits, infiltrating joints and degrading materials over time. In a long-term lunar habitat, such infiltration could pose serious health risks, including respiratory issues and equipment failure.

Moreover, lunar dust is electrostatically charged due to constant exposure to solar wind and ultraviolet radiation. This causes it to levitate and cling to surfaces, making it nearly impossible to brush off. Traditional sealing methods used in Earth-based environments—such as rubber gaskets or lubricated joints—are ineffective against such tenacious particles. A new approach to sealing technology is required, one that accounts for both the physical and electrostatic properties of lunar dust.

Innovations in Sealing Design

Recent advancements in materials science have led to the development of multi-layered sealing systems designed specifically for lunar workwear. One promising approach involves the use of magnetic sealing, where flexible magnetic strips create a tight, adjustable barrier that repels charged dust particles. These strips can conform to the contours of suit joints, ensuring no gaps are left exposed. Additionally, self-healing materials are being tested—polymers that can automatically repair small punctures caused by abrasive dust, preventing further infiltration.

Another breakthrough comes in the form of electrodynamic shielding. By embedding conductive fibers into the outer layers of workwear, engineers can generate a weak electric field that actively repels dust particles. This technology, inspired by NASA’s earlier experiments with dust-resistant coatings, could be integrated into gloves, boots, and helmet seals to prevent dust from entering critical areas. Early prototypes have shown significant promise in vacuum chamber tests, though field testing on the Moon will be the ultimate proving ground.

The Human Factor: Mobility vs. Protection

While robust sealing is essential, lunar workwear must also allow for a full range of motion. Astronauts performing construction, maintenance, or scientific tasks cannot afford to be hindered by stiff or cumbersome suits. Designers are grappling with the challenge of balancing impermeability with flexibility. One solution under exploration is the use of segmented, overlapping plates—similar to medieval armor—that slide smoothly over one another while maintaining a dust-proof barrier. These plates could be made from advanced composites that resist abrasion while remaining lightweight.

Another consideration is the need for easy donning and doffing. In a lunar habitat, astronauts will need to frequently transition between pressurized and unpressurized environments. Sealing mechanisms must be intuitive and quick to engage, minimizing the risk of human error. Some concepts include rotating locking rings or vacuum-sealed zippers that create an airtight bond with a simple twist or pull. These designs aim to reduce the time spent on suit maintenance, a critical factor in mission efficiency.

The Road Ahead: Testing and Implementation

Before these sealing technologies can be deployed, they must undergo rigorous testing in simulated lunar environments. Vacuum chambers, regolith simulants, and parabolic flights are being used to evaluate performance under realistic conditions. Private space firms, in collaboration with national space agencies, are accelerating these efforts, recognizing that effective dust mitigation will be a cornerstone of sustainable lunar habitation.

Looking forward, the lessons learned from lunar workwear design may also benefit other off-world endeavors. Mars, with its own dusty environment, presents similar challenges. The innovations developed today could pave the way for future colonies beyond the Moon, ensuring that humanity’s expansion into space is both safe and practical.

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025

By /Jul 16, 2025